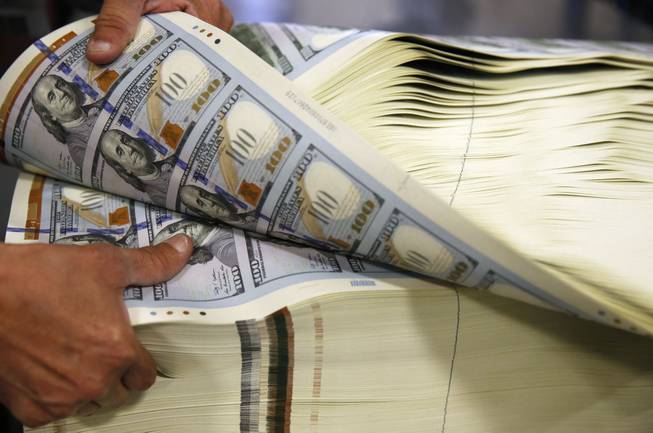

Vernon Bryant/The Dallas Morning News / AP

In a Wednesday, April 20, 2016, photo, Juan Reyna works on aerating a stack of $100 notes before a digital inspection at the Bureau of Engraving and Printing in Fort Worth, Texas. This helps keep the machine from getting a paper jam during the inspection process.

Tuesday, May 17, 2016 | 2 a.m.

FORT WORTH, Texas— Past a field where cattle still graze, about 13 miles from Fort Worth's vibrant Sundance Square, behind a guarded perimeter fence and a sprawling parking lot, huge machines groan and hum, churning out what may be the world's most coveted item.

The product? Money. Greenbacks. Cold, hard cash.

And it's here, in a high-tech Cowtown factory — not Washington, D.C. — that most of it is printed.

The Dallas Morning News reports newcomers to Dallas and even some longtime Texans may not realize that more than half of the nation's paper currency is printed in their own backyard.

But over the last couple of decades, what started out as a 288,000-square-foot building meant to produce just a quarter of the money printed in a given year has grown to a 750,000-square-foot operation with 600 employees, about 250 contractors and 11 unions.

This fiscal year, the Bureau of Engraving and Printing's Western Currency Facility is set to print $164.7 billion of the $213 billion total ordered by the Federal Reserve.

That growth, said Charlene Williams, the bureau's associate director for manufacturing, is a testament to the innovative work of employees.

"They're proud of what they do," she said before a recent tour of the facility. "You ask what (employees) do and they can say they make money — and they really do."

Williams said the bureau explored building its new factory in dozens of cities around the country.

Fort Worth rolled out the red carpet, Williams said. It beat out 80 other locales, including top finalists Las Vegas and Denver.

Bill Thornton, CEO of the Fort Worth Chamber of Commerce, said then-Mayor Bob Bolen worked with then-House Speaker Jim Wright — who championed Tarrant County for decades before resigning amid a storm of ethics accusations — to nail down the deal.

Businessman Bill Harvey agreed to donate the 100 acres for the facility.

"Obviously there had been a great deal of effort put into trying to land that investment here in the community," Thornton said. "They're definitely a major employer — quality jobs, quality benefits."

Williams, who works in both Washington, D.C., and Fort Worth, said that when the bureau first started recruiting in the Fort Worth area, it was on the heels of the last major oil bust, which meant that there were lots of people looking for work.

For the first 100 jobs, she recalled, 14,000 applications rolled in.

Now the facility buzzes with activity, a combination of age-old printing techniques and finely calibrated mass production.

Walk through the revolving doors onto the factory floor and you'll be greeted by a familiar scent: It's like, well, fresh cash. School kids peer out over the floor from an elevated walkway.

Pass through metal cages that secure the production even further and you'll find workers tending to tall stacks of bills, which dry for 72 hours between various stages of printing.

Most of them are printed in 32-note sheets, but Williams was proud to show off a Rube Goldberg-esque apparatus that's almost half the length of a football field.

"It's kind of entertaining to watch," said Gary Willenborg, who manned the machine during that recent tour, as sheets of $1 bills zipped along a conveyer belt, at one point routing over a tall doorway — to accommodate, the story goes, a particularly statuesque press worker.

The Large Examining Printing Equipment will eventually print 50-note sheets of larger denominations, he said.

Across the floor, a worker smoothed a stack of $100 bill sheets, their pastel background palettes like water colors behind the crisp portraits of Benjamin Franklin, hand-engraved by bureau employees who learned their craft over 10-year apprenticeships.

Soon, the engravers will add $20 bills with the face of Harriet Tubman to their repertoire.

The worker spotted a sheet that didn't pass muster, picked it up and crumpled it. The machines kept humming.

Join the Discussion:

Check this out for a full explanation of our conversion to the LiveFyre commenting system and instructions on how to sign up for an account.

Full comments policy